Washing

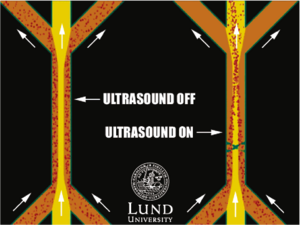

Washing is defined as moving particles or cells from one buffer to another. Petersson et al. developed a microfluidic device where particles in a laminar flow are continuously translated from one medium to another with virtually no mixing of the two media. 5µm polyamide spheres suspended in distilled water spiked (contaminated) with Evans blue, were switched over to clean distilled water. More than 95% of the polyamide spheres could be collected in the clean medium while removing up to 95% of the contaminant. Preliminary experiments to use this method to wash blood were performed. Red blood cells were switched from blood, spiked with Evans blue, to clean blood plasma. At least 95% of the red blood cells (bovine blood) could be collected in clean blood plasma while up to 98% of the contaminant was removed.

The washing concept was improved further by Augustsson et al. (Lab Chip 2009). By adding another washing step, the sequential washing device enabled washing efficiencies of particles from dissolved species (Evans blue) ranging up to 99.995%. Moreover, the throughput of particles was ~5 x 105 s-1 with a particle recovery of ~75%. An application for microbead based sample preparation in complex proteomic samples were further shown, where phosphopeptide extraction was performed. Also, affinity specific extraction of phage particles using acoustophoretic washing has proven possible, yielding suppression ratios of 1 to 100 ppm for unbound material.

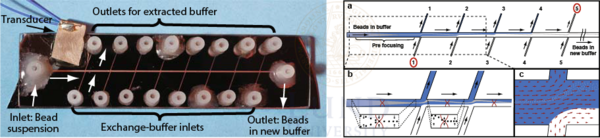

A different approach was suggested by Augustsson et al. (2009) The acoustic radiation force was utilized to confine particulate matter to the centre of a buffer exchange channel while particle free buffer is sequentially aspirated via capillaries that branch off from the buffer exchange channel. At each such branch, clean buffer is supplied at an equal flow-rate from a capillary at the opposing channel wall, generating a sideways translation of the original buffer, laminated with a wash buffer stream. Each such junction increases the buffer exchange ratio accordingly.

The reported buffer exchange system provides means to adjust buffer exchange conditions on-line by tuning the ratio of the cross-flow wash buffer relative the sample suspension flow rate. The system performance was evaluated using 5 μm polystyrene microbeads and a dye as the model contaminant. Wash efficiencies up to 96.4% were accomplished with a 0.2% solid content bead suspension, using eight cross-flow junctions, effectively exchanging the carrier buffer twice. The corresponding data for erythrocyte washing was recorded to be 98.3% at a haematocrit of 2%.

References

Petersson F. et al., Carrier Medium Exchange through Ultrasonic Particle Switching in Microfluidic Channels, Anal. Chem., 2005, 77, 1216-1221

Augustsson P. et al., Decomplexing biofluids using microchip based acoustophoresis, Lab Chip, 2009, 9, 810–818

Augustsson P. et al., Buffer medium exchange in continuous cell and particle streams using ultrasonic standing wave focusing, Microchim. Acta, 2009, 164:269–277